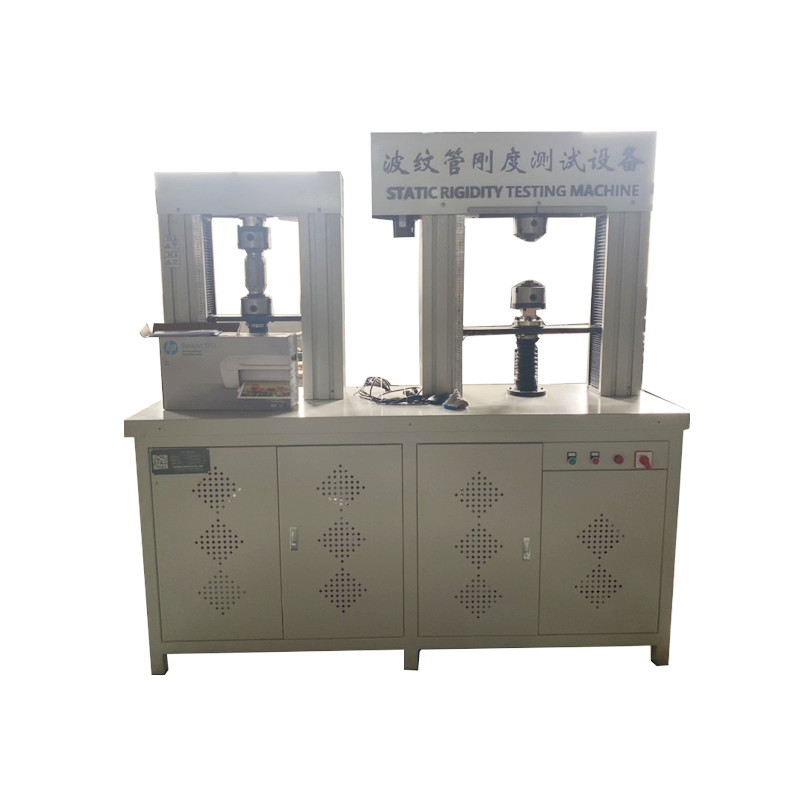

Description

Exhaust Pipe Production Line

Tube Welding Machine

Size range: DN20-DN150

Wall thickness: 0.2-0.6mm

Welding speed:0.8-2.0m/min

Control: Frequency conversion speed control

Welding method: Argon-arc

Welding Welding machine: Panasonic or KEMPPI welding machine

Option 1:Horizontal Hydroforming Bellow Forming machine

Option 2:Vertical Hydroforming Bellow Forming machine

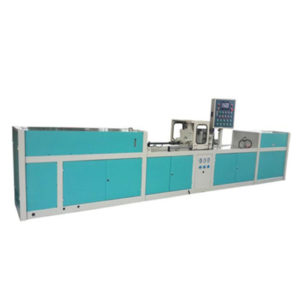

Interlock hose making machine(ID:38-150)

Interlock hose making machine(ID:38-150)

Available Shape: round or polygonal with different forming dies.

Size range: ID38-150

Forming speed: 150-350m/8hrs

Strip thickness: 0.25-0.5mm

Strip width: 16 and 20mm

Power:4KW

Outer dimensions: 3500mm*1200*1600mm

Weight: 950kgs

48 carrier wire braiding machine

-Braiding grail 1 unit

-Caterpillar 1 unit

-Bobbin, carrier 48 units

Technical parameter:

Braiding diameter (mm): 30-75

Carrier rotation speed (r/min): 7.25

Braiding angle: 54°44”

Braiding pitch (mm): 66-166

Pulling speed (M/H): 29-72 Carrier NO.: 48

Motor power (KW): Y132M2-6 5.5kw; Y112M-4 4.0kw Dimension (L*W*H): 4150*1830*1900

Machine Weight: 5000 Kgs

Oil motor power: 2.2KW

2. Working principle

The speed-adjusting point machine drives the gearbox

3. Dimension L: 1.6m *W: 0.8m *H: 1.2m

Including 4 sets of toolings for 4 sizes Power:2.2KW

Speed:1600pcs/8hr

Size range: ID40-ID80 Including two sets of toolings Power:2.2KW

Including two sets of toolings for 4 sizes

Speed:2800pcs/8hr

2.It would be helpful if you directly send us the technical drawing of exhaust pipe.

Reviews

There are no reviews yet.