Demand for stainless steel braided water supply hoses remains resilient, supported by ongoing home renovation, water heater replacement cycles, and a clear shift toward safer, longer-life plumbing connections. Industry reports for stainless steel braided/flexible hose categories commonly project mid-single-digit growth in the coming years, driven by construction and retrofit demand. Market.us+2Verified Market Research+2

1) The market is moving from “low price” to “low risk”

Distributors, installers, and brands increasingly prioritize:

-

Leak prevention and consistency (fewer callbacks)

-

Stable performance under temperature/pressure variation

-

Batch traceability (especially for large retail and engineering projects)

At the same time, buyers are aligning purchases with established performance and marking requirements for flexible water connectors (North America commonly references ASME/CSA frameworks).

2) Compliance is becoming a bigger differentiator (not just a checkbox)

For potable-water applications, compliance pressure is rising around lead and drinking-water contact safety. NSF notes updates affecting endpoint devices such as flexible connectors, including tighter lead leaching acceptance decisions in recent standard work.

In the UK market, WRAS-related acceptance continues to be a practical purchasing gate for many projects.

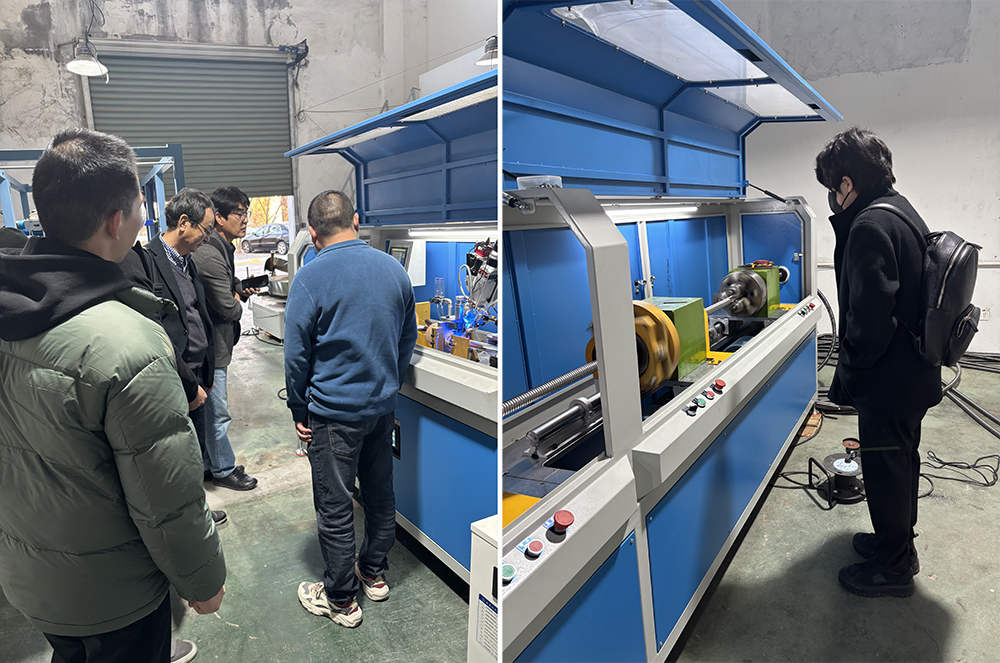

3) What manufacturing buyers care about in equipment (the “why” behind investment)

As the market rewards reliability + compliance, production lines are being upgraded around four priorities:

-

Quality stability at scale: automated control reduces variation between batches and improves consistency.

-

100% testing capability: integrated leak/pressure testing and data logging helps reduce claims and supports audits.

-

Material & process traceability: lot tracking and digital records support brand customers and certification workflows.

-

Flexible production: faster changeover for different lengths/fittings keeps delivery fast for mixed orders.

Our equipment advantages (in one sentence)

We focus on production solutions that help factories deliver consistent quality, verifiable testing records, and compliance-ready manufacturing, so your braided hose products can compete on safety and trust, not only on price.

If you tell me your target market (US/Canada, EU, UK, Middle East, etc.) and your planned hose structure (EPDM liner vs corrugated SS inner tube), I can tailor this news into a slightly more “local” version with the most relevant compliance keywords and buyer concerns for that region.