Description

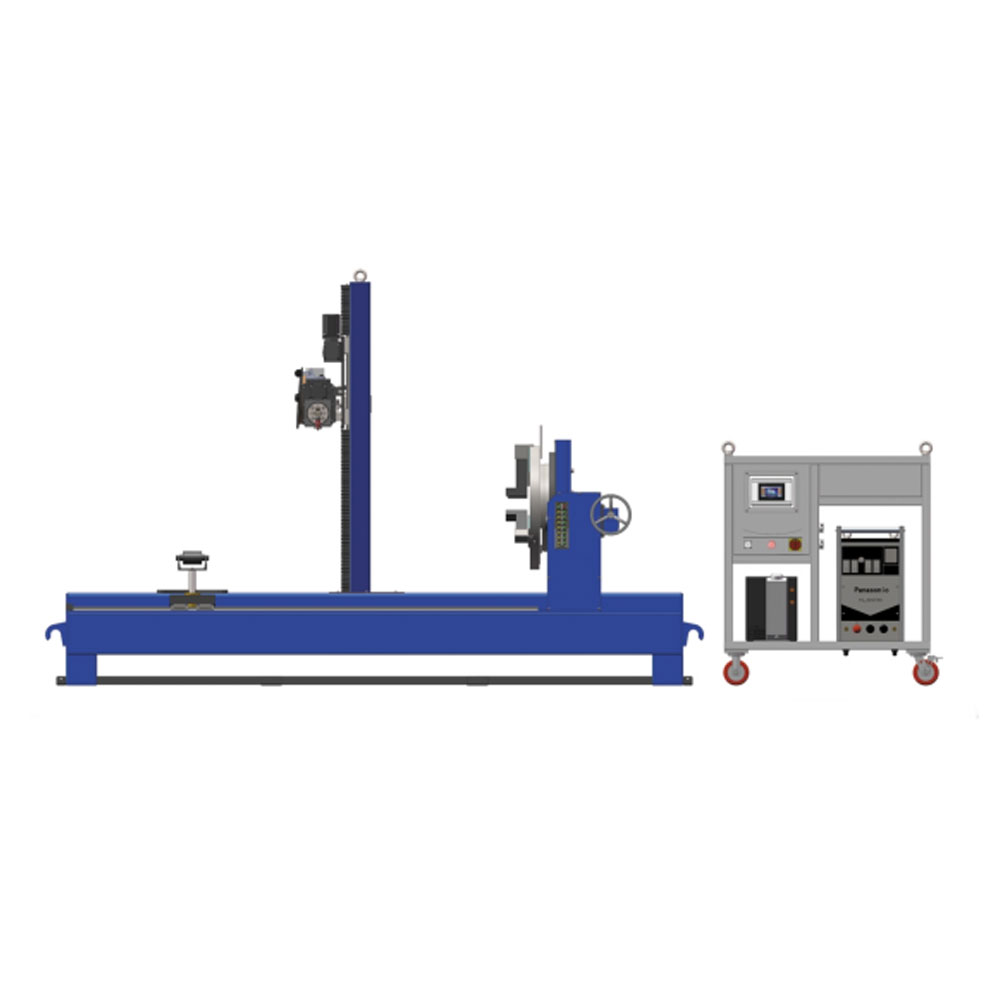

- The whole machine is designed in an integrated way, with compact structure, mature and reliable; the three-claw self-centering chuck rotates and positions accurately.

- Welding operating arm + full-angle positioner + welding gun angle adjustment mechanism ensures the welding gun can be converted to multiple positions and angles.

- The control system adopts a large-screen touch screen human-machine interface, which is easy to program.

- The welding process storage capacity is 30 sets, and the corresponding welding process can be directly called according to the specifications of the weldment by number.

- Arc length adjustment system (AVC) and welding gun horizontal swing system (OSC) are standard.

- CNC automatic wire feeder has automatic reverse wire drawing function and pulsating wire feeding function, and high wire feeding accuracy.

- The forced circulation water cooling system ensures the long-term and reliable operation of the whole machine.

- One-button operation automatically completes the entire welding process; welding parameters can also be intervened in real time as needed.

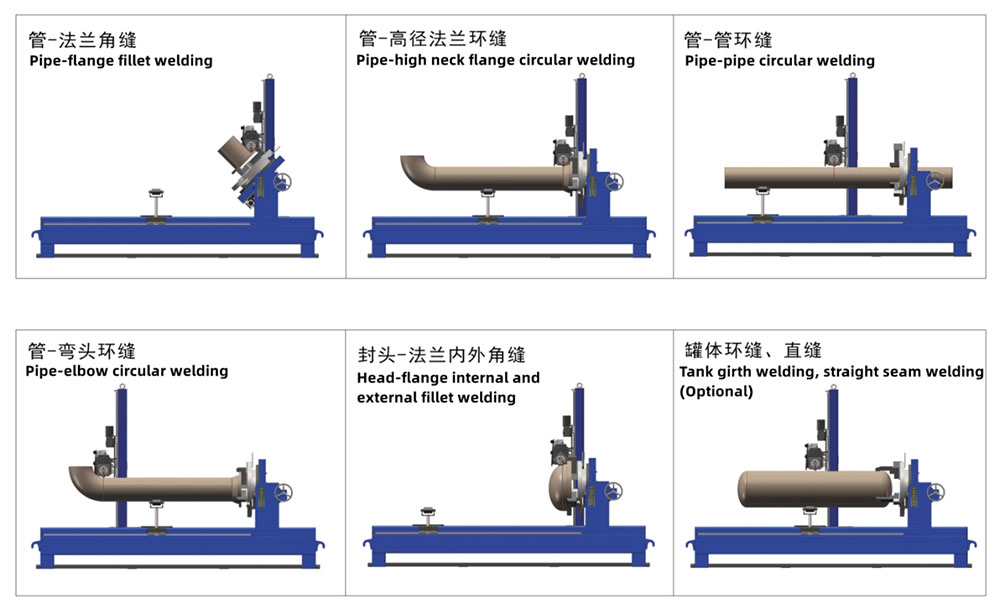

Application

- Welding type: suitable for pipe-to-pipe, pipe elbow, pipe tee, pipe high neck joint; pipe flange, elbow flange angle

- Welding material: suitable for welding of carbon steel, low alloy steel, stainless steel, copper and other materials

- Welding method: can be equipped with argon arc welding equipment

Technical parameters

| Specification Model | H3662-T | H3663-T |

| Welding part type | Butt joint of pipes, pipe elbows, pipe tees, and pipe high-neck flanges; fillet joint of pipe flanges and elbow flanges (straight seam welding function is optional) | |

| Chuck | Center hole 360mm: Clamping outer diameter 50~600mm: Three-jaw self-centering manual chuck (three-jaw self-centering electric chuck optional) | |

| Positioner | 0~90° manual displacement; rotation radius 500mm | |

| Bracket | Suitable for Φ50~Ф600mm; one set is standard (can be added additionally) | |

| Torch oscillator | Swing amplitude 0~20mm; Swing speed 0~20mm/s; Bevel side dwell time 0~5s | |

| Arc length tracker | Tracking range 0~40.0mm; tracking speed 0~6mm/s; arc length tracking accuracy 0.2mm | |

| Automatic wire feeder for argon arc welding | Suitable for wire diameter 1.0mm | |

| Torch | LD400 water-cooled argon arc welding torch; displacement angle 0~90° | |

| Controller | Color touch screen controller | |

| Storage capacity | Can store 30 sets of welding processes (40 sets when straight seam welding is selected) | |

| Number of welding layers | Automatic tiering | |

| Welding power supply | Panasonic YC-400TX TIG welding power supply (optional Panasonic hot wire arc welding power supply) | |

| Motor arm travel (mm)

(XxYxZ) |

2500x900x30 | 3500x900x30 |

| Chuck front travel (mm) | 2000mm | 3000mm |

| Machine weight | 1200kg | 1300kg |

| Input power supply | Welding power supply 30KW/380V/50Hz, control system 1.0KW/220V/50Hz | |