Description

Description

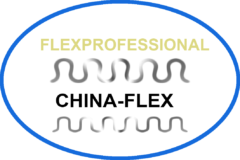

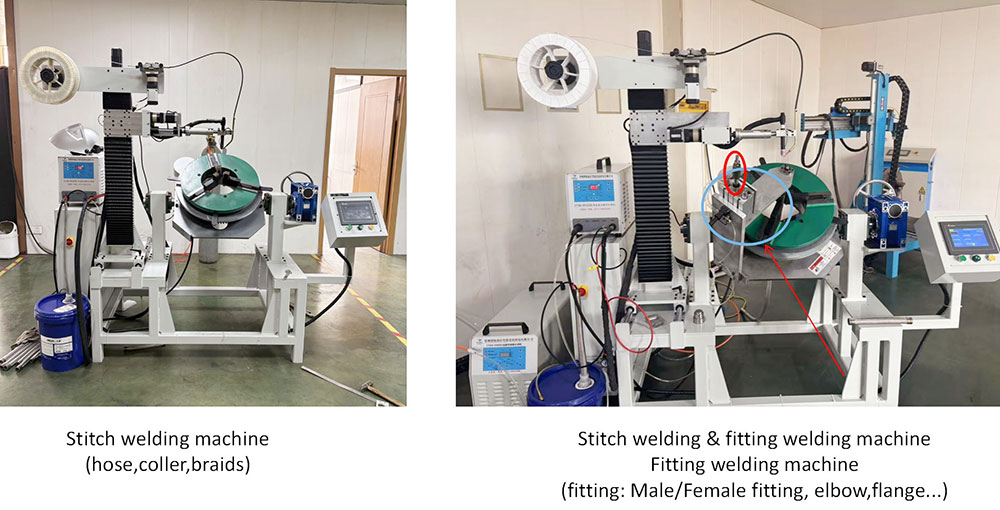

1. One-piece design of the whole machine, compact structure, mature and reliable; three-jaw self-centering lathe chuck rotates and locates accurately

2. Three-dimensional welding operating arm + full-angle positioner + welding gun angle adjustment mechanism, which ensures the multi-position and multi-angle conversion of the welding gun

3. The control system adopts a large-screen touch screen man-machine interface, which is convenient for programming

4. The storage capacity of the welding process is 30 sets, and the corresponding welding process can be directly called according to the specifications of the weldment and according to the number.

5. Standard arc length tracking system (AVC) and welding gun yaw system (OSC)

6. Numerical control automatic wire feeder, with automatic anti-drawing function and pulsating wire feeding function, high wire feeding precision

7. Forced circulating water cooling system to ensure long-term reliable operation of the whole machine.

8. One-button operation, which automatically completes the entire welding process; you can also intervene in real-time welding parameters as needed

Application

Suitable for welding bellows, mesh sleeves, compression sleeve assemblies, elbow, flange, male/female fitting, union, etc…