Principle difference:

l Hydraulic metal hose making machine principle: The pressure of the saponification liquid is used to deform the light pipe by the hydraulic pump, and bulges from the inside to the outside, and then the bulging part is laterally pressed to form regular and regular ripples.

l PU metal hose making machine principle: the PU is squeezed and deformed by the tie rod, so that the light pipe is bulged from the internal deformation, and then the lateral pressure is applied to form regular and regular ripples.

Speed difference:

PU corrugating metal hose machine speed is twice than hydraulic machine

The difference between the produced hoses:

The pipe made by the hydraulic flexible hose machine is U-type, the flexibility is not as good as that of the Ω-shape, and the production process has a saponification liquid. The pipe is not as clean as the pipe made by the PU machine. Tubes with larger diameters and thicker walls can be made because they are not limited by the mold. Due to the use of hydro forming, it is possible to make pipes with a very thick wall, double or triple.

The pipe made by the PU convoluted hose machine is Ω-shape, the flexibility is much better, there is no saponification liquid in the production process, and the produced pipe is cleaner. Due to the limitation of the PU mold, the size of the pipe made is not as large as that of the hydraulic machine, and due to the molding principle, a hose having a too thick wall thickness cannot be made.

Hydraulic or PU should be used for the size overlap:

Depending on the environment in which the hose is used, if the hose is required to have a high degree of flexibility, use the PU metal hose forming machine.

If the hose is required to have a strong pressure bearing capacity and the hose flexibility is not required much, a hydraulic machine can be used.

Best metal hose forming machine manufacturer

Comflex Industrial Co.,Ltd

Comflex Industrial Co.,Ltd is a professional manufacturer of flexible metal hose and bellow forming machine. With over 35 years of technical research, our machines take in a leading position in metal hose machine market.

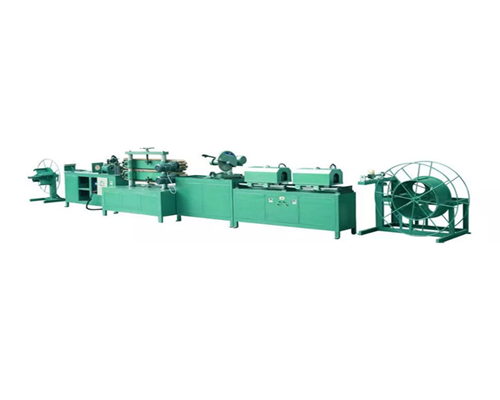

We provide different designed hose&bellow forming machines, such as mechanical hose forming machine, hydraulic hose&bellow forming machine, elastomer machine and etc…covers all the variety of size. And we are still devoting ourselves to improving the technology of machine.

Our excellent machines have been exported to US, Russia, Canada, UK, India, Turkey, Ukraine, Bangladesh, Vietnam and etc…and are running perfectly.

Meanwhile, Comflex established a reliable after-sales service system, which help us win great recognition from our customers. Perfect running machine will be always guaranteed from Comflex.

If you have need in metal hose/bellow forming machine, don’t hesitate to approach to us, we will provide you with most professional solution.